Energy safety decoded

Ren Wei’s laser sensing innovation aims for global benchmark

19 September 2025

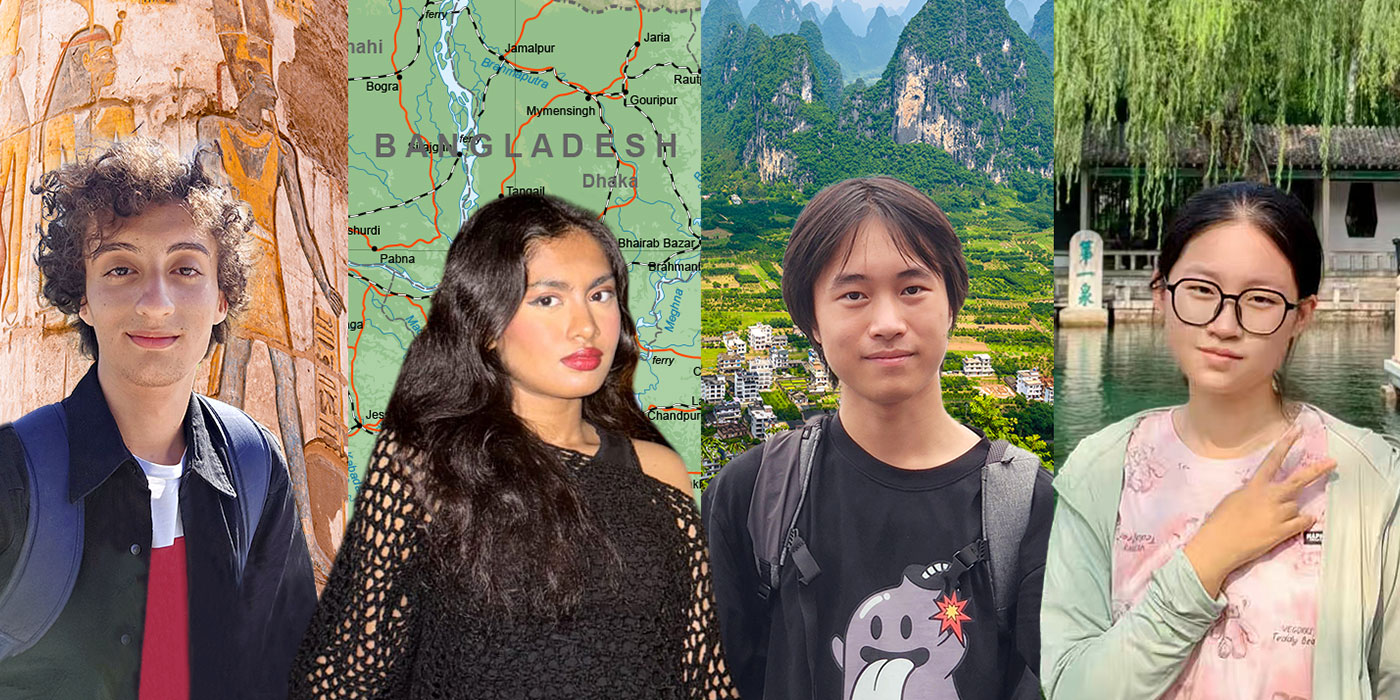

This is part two of our series in CUHK in Focus that talks to principal investigators of the six CUHK projects chosen for the second round of the Hong Kong government’s Research, Academic and Industry Sectors One-plus Scheme (RAISe+). The scheme provides a maximum of HK$100 million to each approved project to help local universities commercialise their research outcomes. Including the seven projects accepted last year, CUHK now has 13 projects receiving RAISe+ funding, the most among local institutions.

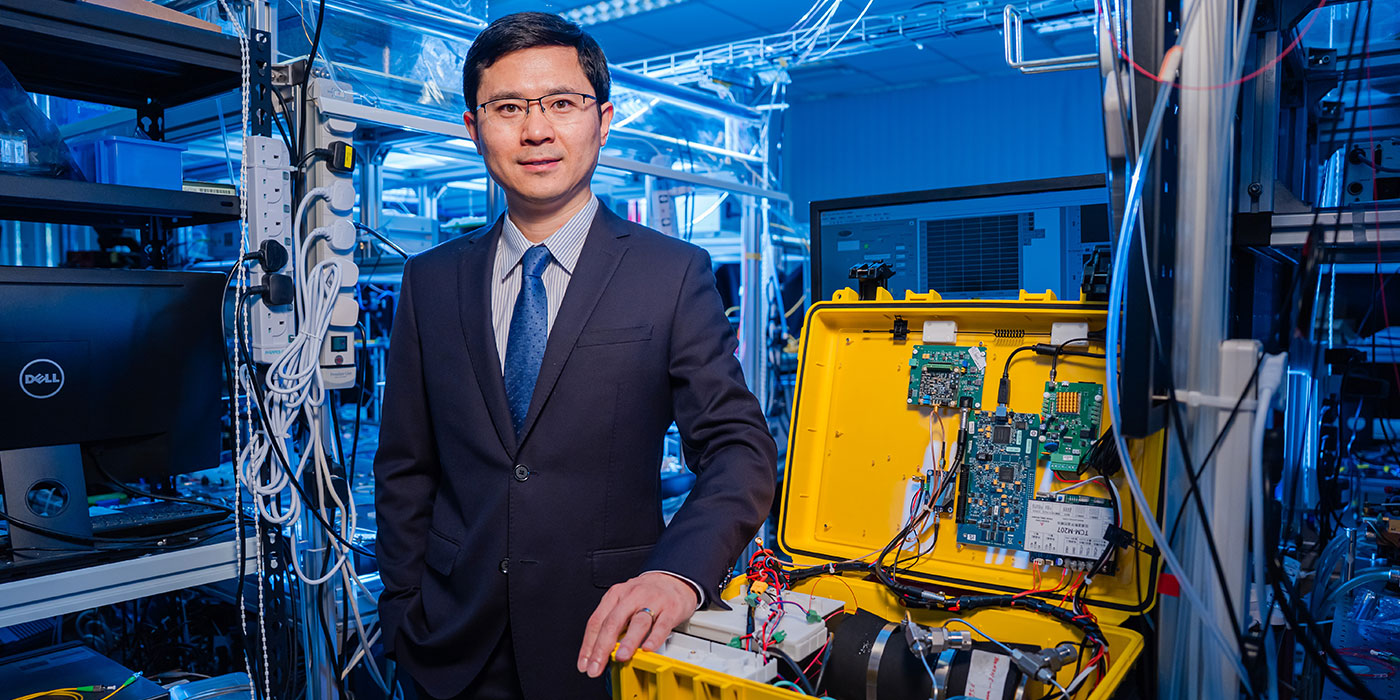

Hong Kong’s outsized role in finance and commerce has long outshone local heavy industry on the world stage. A research project led by Professor Ren Wei from CUHK’s Department of Mechanical and Automation Engineering might just reshape the future of industrial development globally.

The project centres on using lasers to detect and analyse gases, with the aim of improving industrial and user safety. In June 2025, Professor Ren’s team secured government funding to commercialise the technology for oil, gas and other energy applications. The ramifications are set to reverberate far beyond Hong Kong’s shores, from China’s vast pipeline networks to power infrastructure in the Middle East and shale gas extraction in the United States.

Pioneering technology for the world

Market potential was a strong motivator behind the project, aided by the technical expertise of Professor Ren’s team. He explains how their “Intelligent Laser Sensing System for the Energy Industry” would make the world a safer place.

Take hydrogen for example. It is a type of clean energy that the Hong Kong government has promoted in recent years. However, the high leakage risk, wide explosive range and rapid flame spread of the gas pose serious safety challenges, creating both urgency and opportunity for CUHK research to step in.

“Traditional fuels such as oil and natural gas, and emerging low-carbon alternatives like hydrogen, require sensitive and reliable monitoring technologies to analyse their compositions and prevent leaks,” he says.

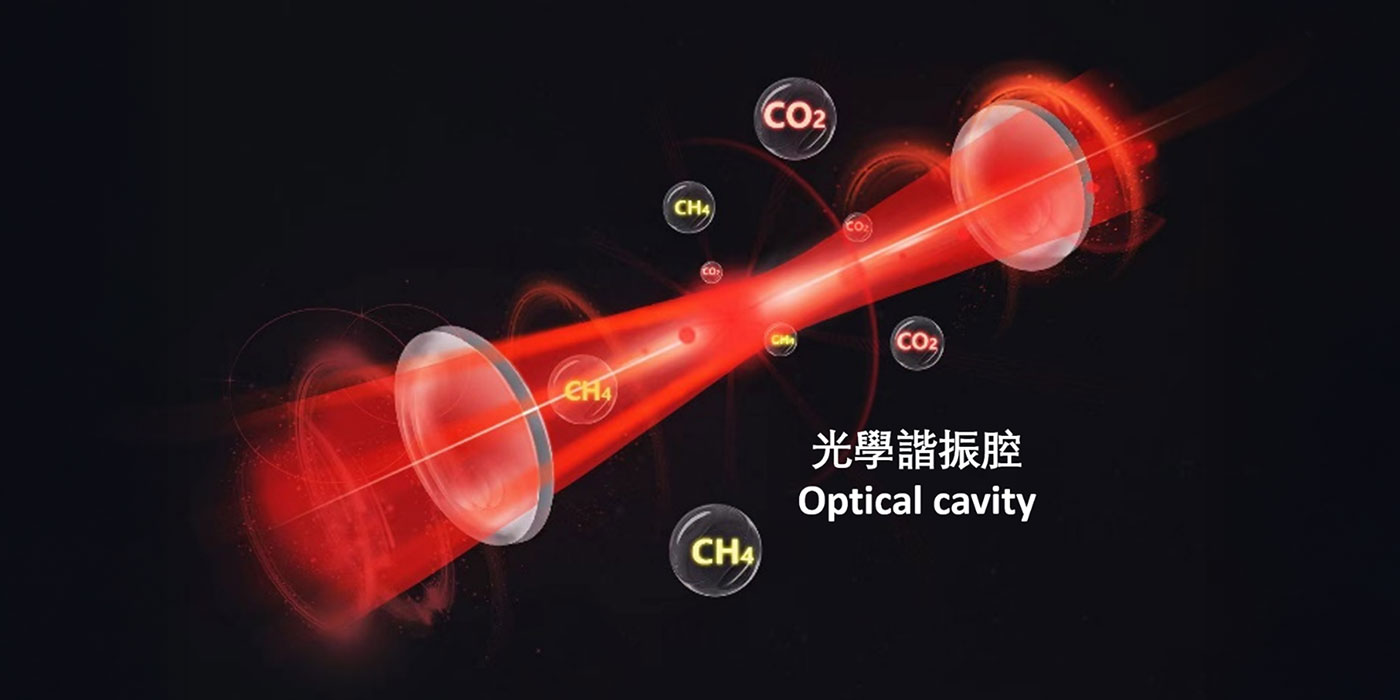

Professor Ren’s lab has developed multiple detection methods for the energy industry based on its decade-long studies about laser spectroscopy. “Laser measurement works by exploiting the selective absorption of specific wavelengths by different gas molecules. Changes in light intensity before and after passing through the gas can be analysed to determine its concentration,” he explains.

The technology is not only fast and precise, but also boasts the highest sensitivity in the world. It is capable of detecting gas concentrations below parts per trillion (ppt, 10⁻¹²) levels.

Moreover, the system can accurately detect dozens of gases, including hydrogen, greenhouse gases, C1-C4 hydrocarbons, and toxic and polluting gases such as sulphur compounds, nitrogen oxides and ammonia, surpassing existing market solutions that typically monitor only one or two. The integrated design further makes the product more cost-effective. “Our lab has mastered cutting-edge spectroscopy technology and built a robust toolbox that can customise detection solutions to various needs,” Professor Ren says.

One of the breakthroughs achieved by the research team is on hydrogen detection. Hydrogen’s extremely weak absorption makes it notoriously difficult to monitor with precision. The team has developed an optical cavity-enhanced approach with a unique laser wavelength that enables detection at parts per million (ppm, 10⁻⁶) levels, which is well below the 4% explosion threshold in air, making hydrogen applications safer.

The project also addresses pipeline leak detection in cities. For instance, Hong Kong’s complex terrain makes many pipelines difficult to reach. The team has developed compact laser sensors that can be mounted on robotic dogs and drones to monitor narrow or inaccessible areas remotely.

From lab to start-up

In 2019, the team founded LaSense Technology Limited, a start-up initially focused on environmental monitoring, such as measuring atmospheric carbon dioxide and methane. LaSense has also worked with local, mainland and international partners on pilot projects. These include collaboration with King Abdullah University of Science and Technology in Saudi Arabia to provide analytical modules for oil industry, and participation in China’s moon exploration to examine moisture in lunar soil. Such partnerships are testimonials of the technology’s reliability and a springboard for global reach.

In Hong Kong, LaSense works with Towngas and CLP Power to detect pipeline leaks and analyse power plant emissions. Due to the global energy transition movement towards net-zero carbon, demand for low-carbon fuels such as natural gas and hydrogen is rising, providing the start-up with ample application and market opportunities.

Reflecting on the journey from lab to real-world application, Professor Ren notes some unexpected challenges. “Industry demands extremely stable equipment that maintains accuracy over long periods, which we did not fully anticipate in the lab. We also have to continuously refine the technology to meet client needs in terms of size, weight and cost.”

Vision for the future

Professor Ren’s project has completed technological development and is now at the second stage of the Innovation and Technology Commission’s RAISe+ Scheme, on track for getting the research outcomes to market.

Over the next two years, the team plans to use the government funding to recruit talent through listed companies and the Quality Migrant Admission Scheme. It also intends to establish a research and assembly centre in Hong Kong for intelligent laser sensing, which would enable in-house packaging of core optoelectronic components and strengthen collaboration with industry partners through pilot programmes to pave the way for mass production.

Supported by the RAISe+ Scheme, this homegrown research project is driving Hong Kong’s reindustrialisation by setting new standards for the start-up ecosystem. At the same time, it is stepping onto the global stage, unlocking new possibilities for the energy sector and sustainable development worldwide.

By Eva Choy

Photos by Steven Yan